For generations, Spain has been a hub for essential oil production, boasting unique endemic species such as thyme, marjoram, rosemary, and sage, contributing to the country’s rich heritage. While Spain remains a leading producer of essential oils, the harvesting and extraction methods have seen minimal evolution, particularly outside of the lavender industry. Recognizing the need for a transformation, Zalabí embarked on a journey to modernize essential oil production, combining traditional techniques with 21st-century sustainability.

For starters, Zalabí’s focus on producing pure and natural essential oils from native aromatic plants is not coincidental but a conscious decision to cultivate well-adapted species. This effort aims to protect biodiversity and avoid depleting natural resources.

In the pursuit of innovation, Zalabí faced the challenge of upgrading the outdated practices of biomass boilers. Despite being cost-effective, these boilers posed environmental and operational issues. The transition to gas/diesel boilers in the essential oil industry offered a seemingly cleaner alternative, eliminating the dark smoke generated from burning biomass. However, it left behind substantial biomass residue, creating challenges in disposal and the associated environmental impact. Zalabí envisioned a model that could bridge the gap between the 19th-century technology of steam distillation and the demands of the present day.

Clean Energy, Minimum Impact

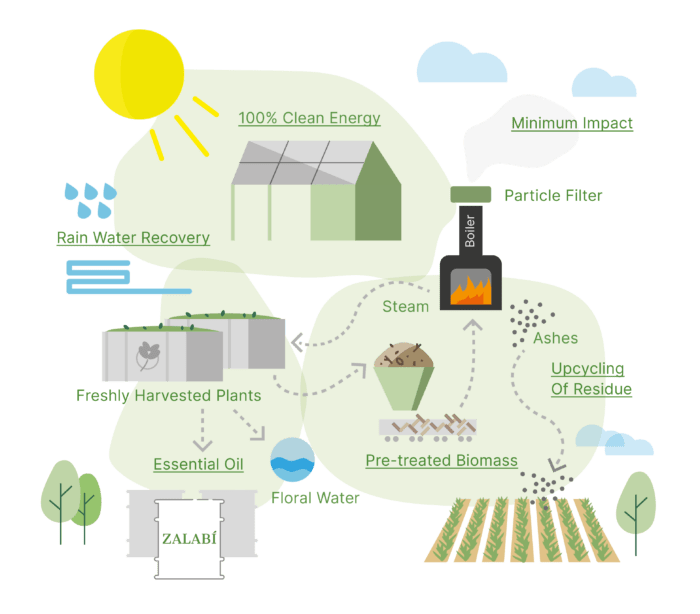

At the heart of Zalabí’s revolution is its off-the-grid distillery, powered exclusively by solar energy. The innovative use of a re-engineered biomass boiler, automatically fed with pre-treated biomass in a dosable format, ensures steady temperature and pressure parameters, mimicking fossil fuel boilers without the associated drawbacks. This approach not only enhances efficiency but also mitigates fire and health hazards posed by excess biomass on the distillery’s premises. Additionally, the direct incorporation of a powerful particle filter into the boiler exhaust stack virtually eradicates emissions from the burning of biomass required to create steam.

In short, the residue is totally upcycled, transforming the freshly harvested aromatic plants that enter Zalabí’s distillery into either energy or a final product. All processes are conducted using solar electricity-powered machinery, reducing the production’s environmental impact to an absolute minimum.

Moreover, recognizing water as a crucial resource in Spain, particularly in the region, Zalabí’s facilities incorporate a simple yet ingenious rain recovery system. Rainwater is treated and reused for various purposes such as cooling or irrigation. This underscores our commitment to environmental stewardship and responsible resource management.

The use of state-of-the-art construction materials and the latest industrial equipment positions Zalabí’s facility at the forefront of its time.

Zalabí’s story is a testament to the power of reimagining traditional industries through a sustainability lens, showcasing that a harmonious blend of tradition and innovation can pave the way for a brighter, greener future in essential oil production.

A new approach to essential oils production

Zalabí’s innovative model aims to set a new standard in the industry. The blend of tradition and innovation not only minimizes environmental impact but also proves cost-effective, potentially reshaping the region’s essential oil production landscape in the mid-term.

Zalabí’s sustainability-focused approach has earned recognition, with nominations in awards like the IFSCC’s “Sustainability Challenge” sponsored by L’Oréal and the “Best Sustainable Initiative in the Fragrance Industry” at the Beauty Cluster’s Barcelona Perfumery Congress.

Ramon Fernandez, managing partner at Zalabí explains, “Innovation doesn’t always require groundbreaking inventions but can arise from a thoughtful combination of existing technologies. In our case, innovation is driven by a true commitment to sustainable practices. We take pride in producing 100% Mediterranean pure and natural essential oils in a way that is truly sustainable, socially responsible, and environmentally friendly.”

Check out the article in Perfumer and Flavorist here.